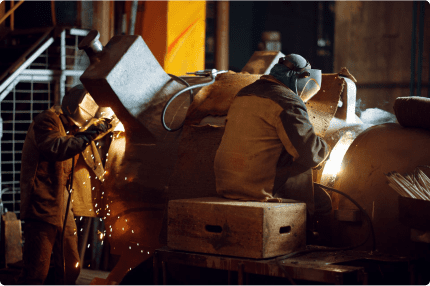

Strong welding is the foundation of safe structural steel, reliable process piping, and long lasting industrial assemblies. Skilled welders do more than join metal. They shape the stability, accuracy, and performance of the entire system. At Brownies Molten Metal, our team has years of field experience working on platforms, frames, stairs, piping systems, hoppers, sheet metal pans, and heavy equipment repairs. This experience allows us to approach each project with a level of precision that directly improves the finished structure.

Industrial facilities depend on welds that can support weight, vibration, pressure, and constant use. Skilled welders understand how to manage these demands from the first cut to the final inspection. Below are key ways trained welders improve both structural and pipe work in real jobsite conditions.

Accurate Fit Up and Joint Preparation

Quality welding begins long before the arc is struck. A skilled welder knows how to prepare joints, align components, and verify measurements so the structure stays true during welding. Poor fit up creates gaps, stress points, and distortion, which can cause misalignment across entire frames or piping runs.

At Brownies Molten Metal, we spend time confirming bevels, cleaning surfaces, and checking each connection. This attention to detail ensures that beams, columns, platforms, and pipe sections line up cleanly when installed.

Understanding Metal Behavior Under Heat

Structural members and piping systems often require multi pass welding. Without proper heat control, these assemblies can warp or twist. Skilled welders understand how metals expand, contract, and react to temperature changes.

Key techniques include:

• Adjusting heat input for thick and thin sections

• Controlling travel speed for deeper penetration

• Using staggered welding sequences to limit distortion

• Allowing cooling periods between passes

This approach keeps structural frames stable and prevents process piping from shifting during installation.

Following Correct Welding Procedures

Each metal type requires its own method. Structural steel, stainless steel, aluminum, and cast iron all react differently to heat, pressure, and filler metals. Skilled welders follow established procedures to maintain strength and consistency.

Examples include:

• Clean root passes for pipe joints

• Proper rod angle for overhead or vertical work

• Controlled shielding gas flow for stainless and aluminum

• Even bead spacing for long structural seams

These habits are part of every project completed by Brownies Molten Metal.

Improving Durability Through Strong Weld Integrity

Industrial structures and piping systems handle stress over long periods. Poor welds fail early, causing downtime, safety concerns, and costly repairs. Skilled welders strengthen the structure by creating welds that resist cracking, fatigue, corrosion, and pressure.

Clean penetration, proper filler selection, and stable bead placement make a major difference in long term performance. These details ensure the structure remains safe throughout regular use.

Reducing Field Adjustments and Installation Delays

When welders produce accurate work in the shop, the installation phase becomes smoother. Skilled welders keep measurements tight, label components correctly, and prepare joints so field teams do not waste time adjusting pieces during assembly.

This improves schedules, lowers labor costs, and reduces downtime for facilities. It is one of the reasons many clients trust Brownies Molten Metal for industrial fabrication and repair work.

Supporting Safer Job Sites

Good welding is also safe welding. Skilled welders inspect equipment, manage cables, maintain ventilation, and follow safe handling of cylinders and materials. A safe environment protects both the team and the structure, which results in cleaner and more precise welds.

Safety is part of the routine in every project completed by Brownies Molten Metal, and it directly improves the final outcome.

Final Thoughts

Skilled welders bring experience, technique, and discipline to every project. Their work improves fit, strength, alignment, and longevity in both structural and pipe systems. For industrial environments that depend on reliable metalwork, working with a trained and experienced team is essential. Through organized processes, careful preparation, and steady workmanship, Brownies Molten Metal provides the level of welding quality that keeps operations safe and productive.