Precision Welding and Fabrication Built for Real Jobsite Demands

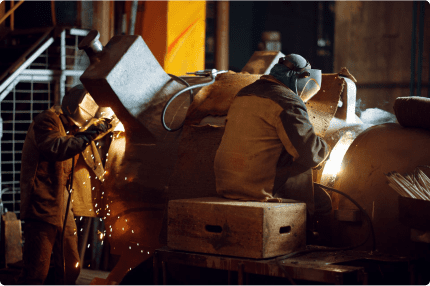

Brownies Molten Metal delivers metalwork shaped by field experience and steady workmanship. From structural assemblies to industrial repairs, each weld is placed with purpose, and every frame is built to hold up under daily use. The team supports contractors, plants, and commercial facilities with metal fabrication that stays accurate, safe, and dependable.

Specializing in industrial platforms, pipe systems, stairs, railings, guards, and custom metal structures.

We Build Strength and Reliability Into Every Weld

Brownies Molten Metal is a women owned shop with a strong background in carbon steel, stainless steel, and aluminum work. The team handles everything from light repairs to full builds for stairs, platforms, guards, pipe systems, and structural assemblies. Each weld is completed with steady control using Stick, MIG, or TIG to match the demands of the project.

Ironwork and Blacksmithing

Supporting industrial and commercial work with durable framing and metal components.

Welding and Fabrication

Reliable welding services shaped by real field experience and consistent craftsmanship.

Clients Who Trust Our Craftsmanship

Brownies Molten Metal supports contractors, facility managers, and industrial teams that depend on accurate metalwork and steady communication. Our projects are built for real production needs, tight schedules, and long service life. Each weld, frame, and assembly is completed with care so clients can move forward with confidence.

From Measured Cuts to Final Fit, We Deliver Quality Metalwork

Brownies Molten Metal is built on field experience, steady craftsmanship, and a clear focus on industrial needs. Every weld, frame, and assembly is created with care so projects stay safe, accurate, and ready for long service. Our team supports contractors and facility managers who need metalwork that performs without issues.

- Years of hands-on trade experience

- Custom fabrication for demanding projects

- Skilled welding across carbon steel, stainless, and aluminum

- Reliable work built around your timeline and layout

- Women owned with a focus on communication

Precision Welding and Fabrication for Industrial Projects

Brownies Molten Metal provides dependable welding and fabrication for contractors, facilities, and production environments that rely on accurate metalwork. Each service is guided by real field experience and steady craftsmanship, helping keep projects safe, aligned, and ready for daily use.

- Structural Steel

- Custom Conveyors

- Mezzanine Fabrication

- Stick Stainless Steel

- Aluminum Fabrication

- Cast Iron Welding

- Sheet Metal Pans

- Hopper Fabrication

- Heavy Equipment Repair

Built to Last with Structural Steel That Performs Under Pressure

From commercial platforms to load-bearing assemblies, structural steel delivers consistent strength in demanding conditions. Its clean finish, reliability under weight, and resistance to warping make it a top choice for stairs, catwalks, and mezzanine frames. Whether it’s supporting an expansive warehouse or a multi-level worksite, this material offers a balance of form and function that stands the test of time.

Steel Builds That Stay True from Start to Finish

- Clean cuts allow for quicker welding

- Prefabricated lengths reduce on-site waste

- Easily braced across long spans

- Compatible with protective coatings

- Holds alignment under dynamic loads

Custom Conveyors That Keep Your Line Moving Smoothly

Efficient production requires flow, and that’s exactly what custom conveyors deliver. These systems are designed to fit your workspace, product type, and material weight, ensuring a seamless handoff from one process to the next. When equipment matches your actual needs, every step becomes quicker, safer, and more reliable. That’s why many operations choose custom conveyors to maintain control without slowing down.

Smart Facilities Rely on Better Conveyor Planning

- Sized to your facility’s footprint

- Reduce manual lifting and fatigue

- Built to carry variable loads and parts

- Integrate with automation and sensors

- Lower the risk of material jams and slowdowns

Mezzanine Fabrication That Maximizes Vertical Space Without Expanding Your Footprint

When floor space runs out, but the ceiling’s wide open, mezzanine fabrication becomes the smart solution. Adding a custom platform allows facilities to double usable space without moving locations or building out. Whether you need more room for storage, equipment, or safe walkways, mezzanine fabrication gives you structure, safety, and strength in one well-planned build. It’s a solution made for industrial flexibility and long-term reliability.

Built to Fit Your Workflow, Not the Other Way Around

- Made to match your exact layout and ceiling height

- Includes safe access stairs and guardrails

- Supports equipment, pallets, or personnel with ease

- Designed to meet safety and code requirements

- Engineered to allow overhead clearance below

Stick Stainless Steel Welds That Hold Up Under Pressure

In demanding environments, stick stainless steel welding is a strong choice for building, repairing, or reinforcing heavy-duty components. It’s especially effective in outdoor or high-heat settings where precision meets durability. From structural rails to equipment frames, this method allows for solid joints that won’t back down when exposed to corrosion, vibration, or load stress.

What Makes Stick Welding a Go-To for Stainless Projects

- Works well in outdoor or windy conditions

- Doesn’t require shielding gas systems

- Good penetration on thicker materials

- Effective for flat, vertical, or overhead welding

- Can handle moisture or surface irregularities

Aluminum Fabrication That Delivers Strength Without the Weight

In industries where corrosion resistance, lightweight strength, and clean finish matter, aluminum fabrication is the clear choice. It’s widely used for platforms, access systems, machine guards, and more. Aluminum offers stability without adding bulk, making it perfect for builds where load needs to be managed carefully. With proper cuts, welds, and bracing, aluminum fabrication supports daily operations with durable, clean results.

Why Aluminum Gets the Job Done for Tough Demands

- Resists rust and moisture in high-use areas

- Allows easier lifting and installation

- Maintains strength across long spans

- Welds cleanly with proper techniques

- Compatible with polished or textured finishes

Cast Iron Welding That Restores Strength Where It Matters Most

When industrial parts crack or break, cast iron welding becomes essential for recovery without replacement. This process takes skill, precision, and the right techniques to avoid further damage. Cast iron, known for its rigidity and brittleness, demands slow heating, careful cooling, and specialized filler. When done right, cast iron welding returns broken components to working condition and prevents costly downtime.

What Makes Cast Iron Repair a Technical Process

- Requires temperature control before and after welding

- Uses nickel or special alloy rods for bonding

- Avoids overheating, which causes stress fractures

- Suitable for engine blocks, pumps, and frames

- Helps extend the life of hard-to-replace parts

Sheet Metal Pans Built for Strength, Fit, and Longevity

Precision and durability are key when it comes to sheet metal pans used in industrial and commercial builds. These pans serve as foundations, catch trays, supports, or structural elements, all while handling weight, moisture, and wear. When fabricated correctly, sheet metal pans prevent failure in the systems they support. The right size, gauge, and finish make them reliable for flooring, equipment bases, or drainage applications.

Why Fabricated Pans Are More Than Just Flat Metal

- Formed from steel, aluminum, or galvanized sheet

- Cut and bent to match tight layout specs

- Welded or riveted for lasting joint strength

- Built to resist corrosion and vibration

- Finished smooth for safety and easy maintenance

Hopper Fabrication In Monroe Detroit MI Built For Storage Flow And Efficiency

Brownies Molten Metal provides hopper fabrication in Monroe Detroit MI for projects that require precise material handling and durable welded assemblies. Each hopper is built to manage the movement, collection, or storage of bulk materials with consistent flow control and strong structural balance.

Keith’s background in pipe fitting and fabrication brings field-ready understanding of welds, joints, and framing. Pamela ensures every project moves smoothly through planning and production. Together, they deliver metalwork that supports both form and function.

The company fabricates hoppers from carbon steel, stainless steel, aluminum, or copper, depending on the application. Each design is engineered for capacity, discharge control, and weight distribution, ensuring dependable operation once installed

Heavy Equipment Repair In Toledo, Ohio, For Industrial Maintenance And Rebuilds

Brownies Molten Metal provides heavy equipment repair in Toledo Ohio for construction, manufacturing, and industrial clients that rely on well-maintained machinery. The service covers welding, fabrication, and mechanical fixes for damaged or worn equipment that must return to operation quickly and safely.

Keith brings decades of experience in welding and fabrication, combining 22 years in pipe fitting with 15 years repairing and building structural steel systems. Pamela coordinates scheduling and communication, keeping every repair job efficient and organized. Together, they manage heavy repair work with consistency and care.

The company handles equipment made from carbon steel, stainless steel, aluminum, and other metals, applying field-tested methods to restore strength, fit, and function.

- Structural Steel

- Custom Conveyors

- Mezzanine Fabrication

- Stick Stainless Steel

- Aluminum Fabrication

- Cast Iron Welding

- Sheet Metal Pans

- Hopper Fabrication

- Heavy Equipment Repair

Built to Last with Structural Steel That Performs Under Pressure

From commercial platforms to load-bearing assemblies, structural steel delivers consistent strength in demanding conditions. Its clean finish, reliability under weight, and resistance to warping make it a top choice for stairs, catwalks, and mezzanine frames. Whether it’s supporting an expansive warehouse or a multi-level worksite, this material offers a balance of form and function that stands the test of time.

Steel Builds That Stay True from Start to Finish

- Clean cuts allow for quicker welding

- Prefabricated lengths reduce on-site waste

- Easily braced across long spans

- Compatible with protective coatings

- Holds alignment under dynamic loads

Custom Conveyors That Keep Your Line Moving Smoothly

Efficient production requires flow, and that’s exactly what custom conveyors deliver. These systems are designed to fit your workspace, product type, and material weight, ensuring a seamless handoff from one process to the next. When equipment matches your actual needs, every step becomes quicker, safer, and more reliable. That’s why many operations choose custom conveyors to maintain control without slowing down.

Smart Facilities Rely on Better Conveyor Planning

- Sized to your facility’s footprint

- Reduce manual lifting and fatigue

- Built to carry variable loads and parts

- Integrate with automation and sensors

- Lower the risk of material jams and slowdowns

Mezzanine Fabrication That Maximizes Vertical Space Without Expanding Your Footprint

When floor space runs out, but the ceiling’s wide open, mezzanine fabrication becomes the smart solution. Adding a custom platform allows facilities to double usable space without moving locations or building out. Whether you need more room for storage, equipment, or safe walkways, mezzanine fabrication gives you structure, safety, and strength in one well-planned build. It’s a solution made for industrial flexibility and long-term reliability.

Built to Fit Your Workflow, Not the Other Way Around

- Made to match your exact layout and ceiling height

- Includes safe access stairs and guardrails

- Supports equipment, pallets, or personnel with ease

- Designed to meet safety and code requirements

- Engineered to allow overhead clearance below

Stick Stainless Steel Welds That Hold Up Under Pressure

In demanding environments, stick stainless steel welding is a strong choice for building, repairing, or reinforcing heavy-duty components. It’s especially effective in outdoor or high-heat settings where precision meets durability. From structural rails to equipment frames, this method allows for solid joints that won’t back down when exposed to corrosion, vibration, or load stress.

What Makes Stick Welding a Go-To for Stainless Projects

- Works well in outdoor or windy conditions

- Doesn’t require shielding gas systems

- Good penetration on thicker materials

- Effective for flat, vertical, or overhead welding

- Can handle moisture or surface irregularities

Aluminum Fabrication That Delivers Strength Without the Weight

In industries where corrosion resistance, lightweight strength, and clean finish matter, aluminum fabrication is the clear choice. It’s widely used for platforms, access systems, machine guards, and more. Aluminum offers stability without adding bulk, making it perfect for builds where load needs to be managed carefully. With proper cuts, welds, and bracing, aluminum fabrication supports daily operations with durable, clean results.

Why Aluminum Gets the Job Done for Tough Demands

- Resists rust and moisture in high-use areas

- Allows easier lifting and installation

- Maintains strength across long spans

- Welds cleanly with proper techniques

- Compatible with polished or textured finishes

Cast Iron Welding That Restores Strength Where It Matters Most

When industrial parts crack or break, cast iron welding becomes essential for recovery without replacement. This process takes skill, precision, and the right techniques to avoid further damage. Cast iron, known for its rigidity and brittleness, demands slow heating, careful cooling, and specialized filler. When done right, cast iron welding returns broken components to working condition and prevents costly downtime.

What Makes Cast Iron Repair a Technical Process

- Requires temperature control before and after welding

- Uses nickel or special alloy rods for bonding

- Avoids overheating, which causes stress fractures

- Suitable for engine blocks, pumps, and frames

- Helps extend the life of hard-to-replace parts

Sheet Metal Pans Built for Strength, Fit, and Longevity

Precision and durability are key when it comes to sheet metal pans used in industrial and commercial builds. These pans serve as foundations, catch trays, supports, or structural elements, all while handling weight, moisture, and wear. When fabricated correctly, sheet metal pans prevent failure in the systems they support. The right size, gauge, and finish make them reliable for flooring, equipment bases, or drainage applications.

Why Fabricated Pans Are More Than Just Flat Metal

- Formed from steel, aluminum, or galvanized sheet

- Cut and bent to match tight layout specs

- Welded or riveted for lasting joint strength

- Built to resist corrosion and vibration

- Finished smooth for safety and easy maintenance

Hopper Fabrication In Monroe Detroit MI Built For Storage Flow And Efficiency

Brownies Molten Metal provides hopper fabrication in Monroe Detroit MI for projects that require precise material handling and durable welded assemblies. Each hopper is built to manage the movement, collection, or storage of bulk materials with consistent flow control and strong structural balance.

Keith’s background in pipe fitting and fabrication brings field-ready understanding of welds, joints, and framing. Pamela ensures every project moves smoothly through planning and production. Together, they deliver metalwork that supports both form and function.

The company fabricates hoppers from carbon steel, stainless steel, aluminum, or copper, depending on the application. Each design is engineered for capacity, discharge control, and weight distribution, ensuring dependable operation once installed

Heavy Equipment Repair In Toledo, Ohio, For Industrial Maintenance And Rebuilds

Brownies Molten Metal provides heavy equipment repair in Toledo Ohio for construction, manufacturing, and industrial clients that rely on well-maintained machinery. The service covers welding, fabrication, and mechanical fixes for damaged or worn equipment that must return to operation quickly and safely.

Keith brings decades of experience in welding and fabrication, combining 22 years in pipe fitting with 15 years repairing and building structural steel systems. Pamela coordinates scheduling and communication, keeping every repair job efficient and organized. Together, they manage heavy repair work with consistency and care.

The company handles equipment made from carbon steel, stainless steel, aluminum, and other metals, applying field-tested methods to restore strength, fit, and function.

- Structural Steel

- Custom Conveyors

- Mezzanine Fabrication

- Stick Stainless Steel

- Aluminum Fabrication

- Cast Iron Welding

- Sheet Metal Pans

- Hopper Fabrication

- Heavy Equipment Repair

Built to Last with Structural Steel That Performs Under Pressure

From commercial platforms to load-bearing assemblies, structural steel delivers consistent strength in demanding conditions. Its clean finish, reliability under weight, and resistance to warping make it a top choice for stairs, catwalks, and mezzanine frames. Whether it’s supporting an expansive warehouse or a multi-level worksite, this material offers a balance of form and function that stands the test of time.

Steel Builds That Stay True from Start to Finish

- Clean cuts allow for quicker welding

- Prefabricated lengths reduce on-site waste

- Easily braced across long spans

- Compatible with protective coatings

- Holds alignment under dynamic loads

Custom Conveyors That Keep Your Line Moving Smoothly

Efficient production requires flow, and that’s exactly what custom conveyors deliver. These systems are designed to fit your workspace, product type, and material weight, ensuring a seamless handoff from one process to the next. When equipment matches your actual needs, every step becomes quicker, safer, and more reliable. That’s why many operations choose custom conveyors to maintain control without slowing down.

Smart Facilities Rely on Better Conveyor Planning

- Sized to your facility’s footprint

- Reduce manual lifting and fatigue

- Built to carry variable loads and parts

- Integrate with automation and sensors

- Lower the risk of material jams and slowdowns

Mezzanine Fabrication That Maximizes Vertical Space Without Expanding Your Footprint

When floor space runs out, but the ceiling’s wide open, mezzanine fabrication becomes the smart solution. Adding a custom platform allows facilities to double usable space without moving locations or building out. Whether you need more room for storage, equipment, or safe walkways, mezzanine fabrication gives you structure, safety, and strength in one well-planned build. It’s a solution made for industrial flexibility and long-term reliability.

Built to Fit Your Workflow, Not the Other Way Around

- Made to match your exact layout and ceiling height

- Includes safe access stairs and guardrails

- Supports equipment, pallets, or personnel with ease

- Designed to meet safety and code requirements

- Engineered to allow overhead clearance below

Stick Stainless Steel Welds That Hold Up Under Pressure

In demanding environments, stick stainless steel welding is a strong choice for building, repairing, or reinforcing heavy-duty components. It’s especially effective in outdoor or high-heat settings where precision meets durability. From structural rails to equipment frames, this method allows for solid joints that won’t back down when exposed to corrosion, vibration, or load stress.

What Makes Stick Welding a Go-To for Stainless Projects

- Works well in outdoor or windy conditions

- Doesn’t require shielding gas systems

- Good penetration on thicker materials

- Effective for flat, vertical, or overhead welding

- Can handle moisture or surface irregularities

Aluminum Fabrication That Delivers Strength Without the Weight

In industries where corrosion resistance, lightweight strength, and clean finish matter, aluminum fabrication is the clear choice. It’s widely used for platforms, access systems, machine guards, and more. Aluminum offers stability without adding bulk, making it perfect for builds where load needs to be managed carefully. With proper cuts, welds, and bracing, aluminum fabrication supports daily operations with durable, clean results.

Why Aluminum Gets the Job Done for Tough Demands

- Resists rust and moisture in high-use areas

- Allows easier lifting and installation

- Maintains strength across long spans

- Welds cleanly with proper techniques

- Compatible with polished or textured finishes

Cast Iron Welding That Restores Strength Where It Matters Most

When industrial parts crack or break, cast iron welding becomes essential for recovery without replacement. This process takes skill, precision, and the right techniques to avoid further damage. Cast iron, known for its rigidity and brittleness, demands slow heating, careful cooling, and specialized filler. When done right, cast iron welding returns broken components to working condition and prevents costly downtime.

What Makes Cast Iron Repair a Technical Process

- Requires temperature control before and after welding

- Uses nickel or special alloy rods for bonding

- Avoids overheating, which causes stress fractures

- Suitable for engine blocks, pumps, and frames

- Helps extend the life of hard-to-replace parts

Sheet Metal Pans Built for Strength, Fit, and Longevity

Precision and durability are key when it comes to sheet metal pans used in industrial and commercial builds. These pans serve as foundations, catch trays, supports, or structural elements, all while handling weight, moisture, and wear. When fabricated correctly, sheet metal pans prevent failure in the systems they support. The right size, gauge, and finish make them reliable for flooring, equipment bases, or drainage applications.

Why Fabricated Pans Are More Than Just Flat Metal

- Formed from steel, aluminum, or galvanized sheet

- Cut and bent to match tight layout specs

- Welded or riveted for lasting joint strength

- Built to resist corrosion and vibration

- Finished smooth for safety and easy maintenance

Hopper Fabrication In Monroe Detroit MI Built For Storage Flow And Efficiency

Brownies Molten Metal provides hopper fabrication in Monroe Detroit MI for projects that require precise material handling and durable welded assemblies. Each hopper is built to manage the movement, collection, or storage of bulk materials with consistent flow control and strong structural balance.

Keith’s background in pipe fitting and fabrication brings field-ready understanding of welds, joints, and framing. Pamela ensures every project moves smoothly through planning and production. Together, they deliver metalwork that supports both form and function.

The company fabricates hoppers from carbon steel, stainless steel, aluminum, or copper, depending on the application. Each design is engineered for capacity, discharge control, and weight distribution, ensuring dependable operation once installed

Heavy Equipment Repair In Toledo, Ohio, For Industrial Maintenance And Rebuilds

Brownies Molten Metal provides heavy equipment repair in Toledo Ohio for construction, manufacturing, and industrial clients that rely on well-maintained machinery. The service covers welding, fabrication, and mechanical fixes for damaged or worn equipment that must return to operation quickly and safely.

Keith brings decades of experience in welding and fabrication, combining 22 years in pipe fitting with 15 years repairing and building structural steel systems. Pamela coordinates scheduling and communication, keeping every repair job efficient and organized. Together, they manage heavy repair work with consistency and care.

The company handles equipment made from carbon steel, stainless steel, aluminum, and other metals, applying field-tested methods to restore strength, fit, and function.

"This welding service exceeded my expectations in every way. They not only brought my design concept to life but also improved it with their technical insights. The result was a perfectly fabricated structure that looked great and was structurally sound. Their ability to combine creativity with engineering skill is what sets them apart."

Sintia Dewi Chandra

Client

"This welding service exceeded my expectations in every way. They not only brought my design concept to life but also improved it with their technical insights. The result was a perfectly fabricated structure that looked great and was structurally sound. Their ability to combine creativity with engineering skill is what sets them apart."

Sintia Dewi Chandra

Client

"This welding service exceeded my expectations in every way. They not only brought my design concept to life but also improved it with their technical insights. The result was a perfectly fabricated structure that looked great and was structurally sound. Their ability to combine creativity with engineering skill is what sets them apart."

Sintia Dewi Chandra

Client

These FAQs Help You Understand Our Work Better

We handle carbon steel, stainless steel, aluminum, copper, and specialty alloys depending on the project. This allows us to support structural steel, process piping, sheet metal work, hoppers, platforms, and custom components for many industries.

Yes. We fabricate beams, columns, frames, stairs, and rail systems for warehouses, plants, and commercial facilities. Each section is measured, welded, and inspected to ensure clean alignment and dependable long term performance.

We design and fabricate conveyor systems that fit your layout, load requirements, and workflow patterns. Each conveyor is pre fit in the shop, labeled, and delivered ready for installation to help reduce downtime during setup.

Mezzanines are built from carbon or stainless steel with stairways, guard rails, and decking options. We confirm load requirements, fabricate components in the shop, and assemble them on site with careful alignment and safety checks.

We fabricate and weld piping systems for liquids, gases, steam, and production materials. Our work includes cutting, fitting, welding, adding supports, and preparing sections for installation. Systems are built to match routing plans and pressure demands.

Yes. We produce custom sheet metal pans with precise bends, welded corners, and clean seams that prevent leaks and support continuous use. These pans support machinery, drainage systems, and structural layouts in industrial settings.

We fabricate hoppers designed for flow control, storage, and discharge needs. Each unit is built with correct thickness, shape, reinforcement, and capacity so material moves through the system without issues.

We provide shop and field repair for cracked frames, bent supports, worn parts, and damaged panels. Our process includes inspection, controlled welding, fitting, alignment checks, and final testing to restore safe operation.

Cast iron welding is completed with controlled heating, steady passes, and gradual cooling to prevent cracking. We repair cast housings, stair parts, railings, brackets, and other components while keeping their structural shape intact.

Yes. We fabricate aluminum stairs, platforms, rails, machine guards, and lightweight frames. Every piece is welded and fitted to match precise measurements and reduce unnecessary load on floors or structures.

Let’s Build Strength Together

Our shop works closely with contractors, facility managers, and industrial teams to deliver metalwork that fits your layout and timeline. Reach out for quotes, walkthroughs, or project reviews, and we will guide you through the process from start to finish.

Call Us To:

517-525-4846, 517-759-9373

Visit our at :

Riga, Michigan 49276, United States

Drop to Our Mail :

browniesmmm3@gmail.com

Your Welding Project Starts Here

Brownies Molten Metal is ready to support your next build with accurate fabrication and steady workmanship. Share your details, and our team will respond with clear steps that help move your project forward with confidence.